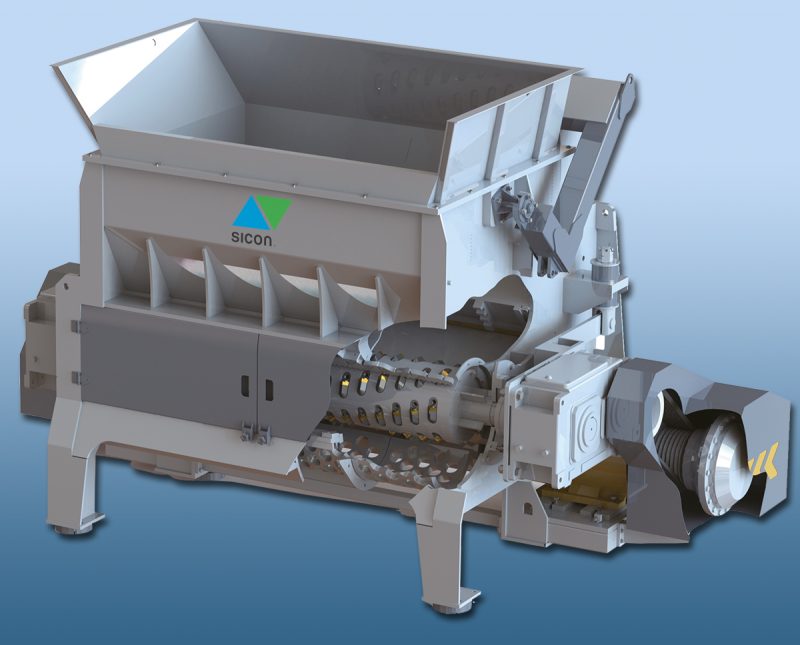

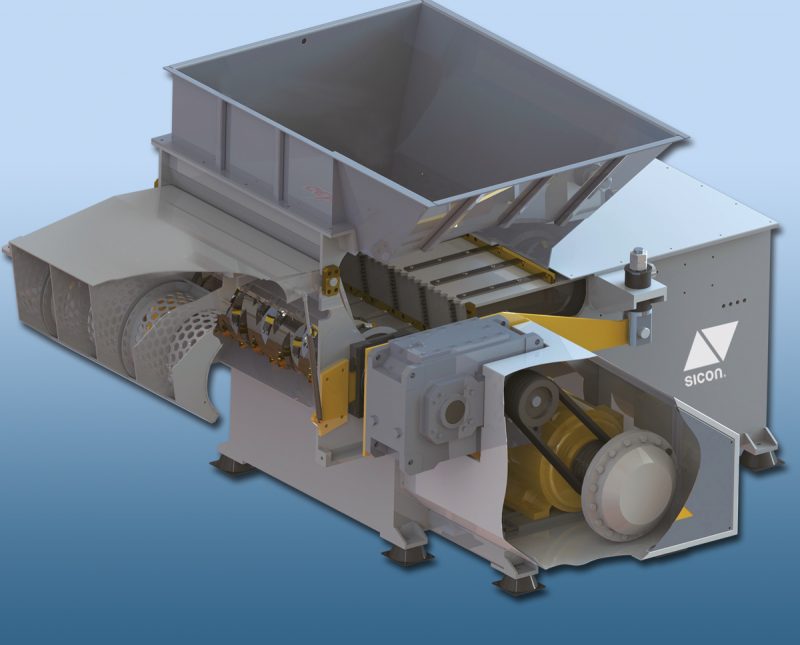

EcoShred® 1SS

Single shaft shredder - Most powerful and cost-efficient shredding

The single-shaft shredder EcoShred® 1SS fits the requirements of a variety of applications and input material. This type of shredding is best suited for dense and bulky material. With its slow-speed and high torque design, noise levels and energy consumptions a greatly reduced while highest throughput is being achieved. The big shredding chamber and feeding hopper with high load capacity, coupled to the SPS-controlled horizontal material pusher, allows for optimum material feeding to the rotor and increases efficient performance levels. The design of the EcoShred® 1SS is further adaptable to specific material requirements and include, among other features, rotor- and cutting tool design and conformation.

SICON’s special design makes the EcoShred® 1SS easy to be install and operate. Due to their design, EcoShred® 1SS can be integrated in existing recovery operations effortlessly. We offer complete planning and delivery of additional conveying and separation equipment to ensure best possible performance and project handling.

Low rotor speed and high torque

Feeding hopper

Rotor with knives

The EcoShred® 1SS single-shaft shredder is available in 3 sizes. They are easy to install and operate.

Typical applications:

- Plastics (mouldings, nuggets, foils, profiles, bales, etc.)

- Wood (pallettes, lumber and carpenter waste, biomass, etc.)

- Paper & cardboard (confidential documents, production waste, packaging material, etc.)

- Aluminum (cans (UBCs), profiles, etc.)

- Textiles & carpet (rolls, tiles, clothes, etc.)

- Secure destruction of counterfeit items, defective goods, expired inventory, etc.

- Cables & wire

- Alternative fuels

EcoShred® 1SS - Your benefits at a glance

- Highly energy-efficient at maximum cutting force

- Shock-absorbing gear box housing reduces stress on drive components

- Rotatable rotor knives can be used on different edges before replacement needed

- Adjustable counter knives consistent cutting performance guaranteed

- Optional feature: form-outside adjustable counter knives

- Fast-to-replace screens for precise size control

- Divided shredder chamber bottom, reinforced with brass and PU-strips

- Stand-alone control panel with SPS System, optional Allen Bradely available

- Certified according to applicable CE/UL safety regulations

Technical parameters

Technical data A-serie

(other sizes upon request, subject to changes)

| EcoShred 1SS-1500-A | EcoShred 1SS-2000-A | |

|---|---|---|

| Dimension (L/W/H) [mm] | 2,230×3,660×2,970 | 2,230×3,710×2,970 |

| Hopper Inlet [mm] | 1,360×1,910 | 1,360×2,410 |

| Discharge Height [mm] | 460 | 460 |

| Ram Travel [mm] | 1,000 | 1,000 |

| Rotor Diameter [mm] | ∅ 480 | ∅ 480 |

| Rotor Operation Length [mm] | 1,600 | 2,100 |

| Rotor Speed [rpm] | 80 | 80 |

| Screen [mm] | ∅ 40 | ∅ 40 |

| Rotor Knives [PCS] | 88 | 95 |

| Counter Knives [PCS] | 3+3 | 4+4 |

| Drive Power-standard [kw] | 110 | 55+55 |

| Hydraulic Power [kw] | 11 | 11 |

| Approx. Weight [kg] | 12,500 | 15,000 |

Technical data b-serie

(other sizes upon request, subject to changes)

| EcoShred 1SS-1500-B | EcoShred 1SS-2000-B | EcoShred 1SS-2200-B | EcoShred 1SS-2800-B | EcoShred 1SS-1800-B | |

|---|---|---|---|---|---|

| Dimension (L/W/H) [mm] | 3,710×2,880×2,2530 | 3,710×4,150×2,530 | 3,920×4,500×2,720 | 3,920×5,600×2,720 | 4,070×4,070×2,870 |

| Hopper Inlet [mm] | 2,080 x 1,880 | 2,080×2,380 | 2,380×2,580 | 2,380×3,180 | 2,530×2,180 |

| Discharge Height [mm] | 720 | 720 | 720 | 720 | 800 |

| Ram Travel [mm] | 1,100 | 1,100 | 1,100 | 1,100 | 1,100 |

| Rotor Diameter [mm] | ∅ 480 | ∅ 480 | ∅ 650 | ∅ 650 | ∅ 800 |

| Rotor Operation Length [mm] | 1,500 | 2,000 | 2,240 | 2,840 | 1,790 |

| Rotor Speed [rpm] | 80 | 80 | 80 | 80 | 80 |

| Screen [mm] | ∅ 40 | ∅ 40 | ∅ 40 | ∅ 40 | ∅ 40 |

| Rotor Knives [PCS] | 84 + 6 | 95 + 6 | 109 + 6 | 125 + 6 | 106 + 6 |

| Counter Knives [PCS] | 3+3 | 4+4 | 4+4 | 5+5 | 3+3 |

| Drive Power [kw] | 90 | 55+55 | 90+90 | 110+110 | 90+90 |

| Hydraulic Power [kw] | 7.5 | 11 | 15 | 15 | 11 |

| Approx. Weight [kg] | 11,100 | 14,800 | 18,000 | 21,000 | 16,000 |

Technical Data C-Series

(other sizes upon request, subject to changes)

| EcoShred 1SS-500-C | EcoShred 1SS-600-C | EcoShred 1SS-800-C | EcoShred 1SS-1000-C | EcoShred 1SS-1200-C | EcoShred 1SS-1500-C | |

|---|---|---|---|---|---|---|

| Dimension (L/W/H) [mm] | 1,820×1,190×1,730 | 1,820×1,310×1,730 | 2,800×1,800×2,090 | 2,800×1,980×2,090 | 2,800×2,500×2,140 | 2,800×2,750×2,140 |

| Hopper Inlet [mm] | 660×500 | 660×600 | 1,080×800 | 1,080×1,000 | 1,080×1,200 | 1,080×1,400 |

| Discharge Height [mm] | 490 | 490 | 565 | 565 | 565 | 565 |

| Rotor Diameter [mm] | ∅ 220 | ∅ 220 | ∅ 400 | ∅ 400 | ∅ 400 | ∅ 400 |

| Rotor Operation Length [mm] | 500 | 600 | 800 | 1,000 | 1,200 | 1,500 |

| Rotor Speed [rpm] | 80 | 80 | 80 | 80 | 80 | 80 |

| Screen [mm] | ∅ 40 | ∅ 40 | ∅ 40 | ∅ 40 | ∅ 40 | ∅ 40 |

| Rotor Knives [PCS] | 19+4 | 23+4 | 35+4 | 45+4 | 55+4 | 78+4 |

| Counter Knives [PCS] | 2 | 2 | 2 | 2+2 | 3+3 | 3+3 |

| Drive Power [kw] | 15 | 18,5 | 37 | 45 | 55 | 75 |

| Hydraulic Power [kw] | 2.25 | 2.25 | 3.75 | 3.75 | 5.5 | 5.5 |

| Hopper Volume [L] | 490 | 670 | 1,220 | 1,440 | 1,660 | 1,880 |

| Approx. Weight [kg] | 1,500 | 1,700 | 4,200 | 4,300 | 5,300 | 7,280 |