VariSort and EcoSort Classic

Multi-Sensor Sorting Systems for Metal Separation

SICON is proud to be the exclusive distributor of SESOTEC sensor sorters for the scrap industry. Our long-standing partner SESOTEC, based in Bavaria, Germany, has been dedicated to delivering optimized technical sensor sor-ting solutions of bulk material to customers for almost 50 years. As one of the global market leaders for sensor technology, SESOTEC is committed to in-house development of new products to always ensure highest-quality for sorting results. The close cooperation with SICON enables the best solutions for the scrap industry. This is reflected in the expansion of the SICON-specific product range to include the EcoSort Classic series for specific use in the scrap and non-ferrous metal industry.

- Universal application possibilities for sorting scrap, metal, electrical scrap, plastics and wood.

- Separation of cables, aluminium, stainless steel, cooper, etc.

- Sorting of Zurik and Zorba into unmixed metal fractions

The following sensors are available:

- Induction sensor for any metals

- Induction sensor for stainless steel

- Optical sensor for shape and color detection

- XT sensor (also combined with camera) / LIBS sensor (NIR sensor/MIR HSI sensor)

- AI-based camera system, also in combination with other sensors

The SICON quality promise

- Excellent manufacturing quality „Made in Germany“

- In-house sensor development and manufacturing enable direct customer-specific configurations

- Highly-reliable, lowest operational costs

- Outstanding technical support

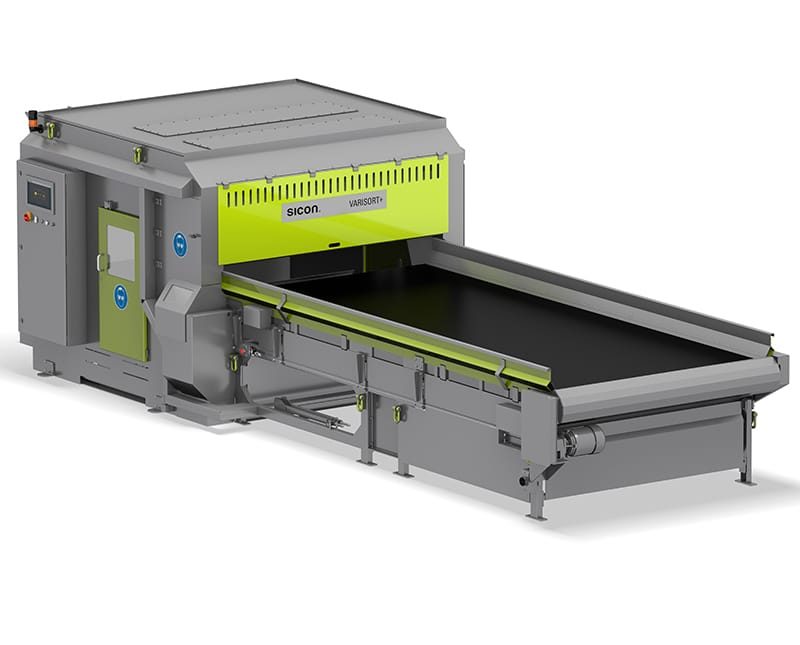

Weltweit im Einsatz - der VariSort

The VariSort series combines the integration of a wide variety of sensors, which can also be combined.

VariSort - Your advantages at a glance

- Variable working widths: 1,000, 1,500, 2,000, 2,800 mm / (40”, 60”, 80”, 110”)

- Combination of different sensor types possible

- Optional parallel sorting of multiple materials on one machine by splitting the belt into different sections

- Extremely easy maintenance

- Very low lifetime costs

Global presence and more than 20 years of experience

Application: Scrap Processing, Spain

The VariSort M is the universal solution for sensor sorting. For the first step of separation of all residual metals from shredder residues after cyclone separation as well as for the separation of stainless steel and cables as separate fractions.

The VariSort M+ is equipped with the Sesodesk software, which enables perfect adaptation to customer-specific requirements. Sorting programs can be created and stored.

Application: Scrap Processing, Georgia, USA

The VariSort XT is a sorter based on X-ray transmission technology and thus on density detection. Its special design makes it possible to detect and separate parts up to 5 mm cleanly. Outstanding features are the maintenance-friendly design of the machine and the extremely high reliability in operation. Most of the sorters we have installed have been running for years without any service intervention.

The VariSort XT is an extremely versatile sorter for the separation of printed circuit boards, cables, non-ferrous metals, aluminum (cast aluminum versus aluminum sheets, aluminum versus zinc and copper components, high chlorine plastics, brominated plastics and much more!

Application: Scrap Processing, Iowa, USA

The VariSort Compact is the ideal machine for the separation of cables, printed circuit boards and non-ferrous metals down to the finest fractions. The machine is equipped with a metal sensor and a high-resolution camera. Here too, the software allows individual configuration of sorting programs according to the requirements of our customers. Our service technicians can access the machine via remote maintenance and thus easily make adjustments if, for example, certain metals should not be included in the target fraction. Of course we are also happy to train your operating personnel on site on request.

Sensor Units for all requirements

Zurik Processing

The VariSort M and the VariSort CM are mainly used in the separation of Zurik. Especially on the American market, dry sorting of metals from ASR has become established. After appropriate screening and classifying steps, the VariSort produces a metal-free waste fraction at very high throughputs.Stainless Steel Separation

Based on a metal and stainless-steel-signal, the VariSort M+ sensor sorter is the number-one choice for mixed stainless steel processing. Equipped with an innovative sensor, the VariSort M+ differentiates precisely between chromium- and ferrous-containing steels delivering outstanding separation results. The VariSort sensor sorter series is characterized by highly customizable sorting configurations and setting options and can be adapted to a wide range of tasks. A typical application for the VariSort M+ is stainless steel recovery from heavy fractions of sink-float-systems. Another application example is stainless steel recovery from dry-separation of mixed-metal-fractions.

Aluminum Processing

Aluminum fractions can be easily processed with the VariSort XRT. Based on X-Ray transmission technology, the VariSort XRT is capable to separates various aluminum cast and wrought alloys. In addition, the VariSort XRT can detect heavy-metal aluminum alloys as well as organic and plastic impurities.

Copper and Brass Separation

The combination of metal-induction and optical sensor make the VariSort CM the ideal sorter for separating red metals from mixed fractions. The highly customizable settings can be configured to a variety of copper and brass applications. The unit’s camera system has been specifically set-up and optimized for highest detection and performance values. Unlike other similar units, the VariSort CM detects and identifies objects in real-time in the trajectory. Different application settings allow even for recovery of fine copper dust e.g. from lead or other metals.

Cable / ICW Processing

Another application example of the versatile VariSort CM is the recovery of cables and insulated-coper-wire (ICW) from shredder residue or e-scrap. Based on a combination of evaluating a metal signal with an object’s shape and color, the VariSort CM separates wires efficiently at highest throughputs. Stainless steel is excluded from being recognized as wire by the VariSort CM. The clean wire fraction, free of any undesired impurities, delivers impressive results for sub-sequent granulating steps.

PC & Circuit Board Processing

Separating PCB & circuit boards from ZURIK, ZORBA and other e-scrap can be easily mastered with the pre-installed application setting on the VariSort CM. Identifying objects reliably based on metal content, shape and color makes PC & circuit board processing economically lucrative.

User Interface Software SesoDesk

All VariSort sensor sorters come equipped with the easy-to-use application software „SesoDesk“. Based on an Octa-Core technology, the software optimizes performance of evaluating multiple sensor signals in real time while providing users with highest flexibility in complex sorting tasks.

Special feature: Inverse sorting

Focusing your sorting efforts on your targeted material does not always make economic sense. An alternative approach is provided by means of inverse sorting. By targeting all non-metal to be separated from metal a clean plastics fraction can be generated easily free of any metallic-impurities. The generated metal fraction can then undergo additional processing steps, as necessary. The practice of inverse sorting is widely applicable, one lucrative example for inverse-sorting is precious-metal processing..

Product video

This video explains how VariSort works and also describes the input and output materials in more detail.

Duration: 4.38 minutes