EcoScan® Online

Online analysis for shredder scrap and non-ferrous metal scrap

The use of shredded scrap for steelproduction has significant metallurgical benefits. Shorter tap-to-tap times, a faster filling of the scrap baskets or the melting furnace and e.g. reduced electrode costs. Nevertheless, the use of shredded scrap in many plants is not only limited due to furnace technology. Rather, increasing quality problems have been revealed in recent years which are clearly visible in successively increasing and extremely fluctuating copper contents.

The incalculable fluctuations limit the use of shredded scrap, especially for those steel grades that allow only a very low copper content. Instead more raw iron or DRI / HBI is often used. As a rule this is associated with higher costs and a poorer CO2 balance but in total safer for production.

With the EcoScan® Online SICON has developed the first reliable and economical online solution that gives permanent transparency of the chemical parameters of the shredded scrap as well as on the bulk density. Thus, the optimum amount of shredded scrap can be added. Worst-case considerations are no longer necessary.

EcoScan®Online

The advantages of online analysis become fully available when they are connected to the SICON ScrapTuning. ScrapTuning is a solution specially developed for steel mills that cleans shredded scrap to achieve guaranteed copper contents of <0.15-0.20 and to increase the FE content through a specific cleaning process.

ScrapTuning makes it possible to upgrade low-quality shredded scrap, which is sometimes cheaper to buy, at a low cost. Shredder scrap thus becomes an alternative to pig iron, DRI / HBI, also for long steel production.

ScrapTuning and EcoScan Online are networked and completely automated. An integration into the control system of the smelting operation is easily feasible. The scrap insert is thus completely transparent and can be optimized.

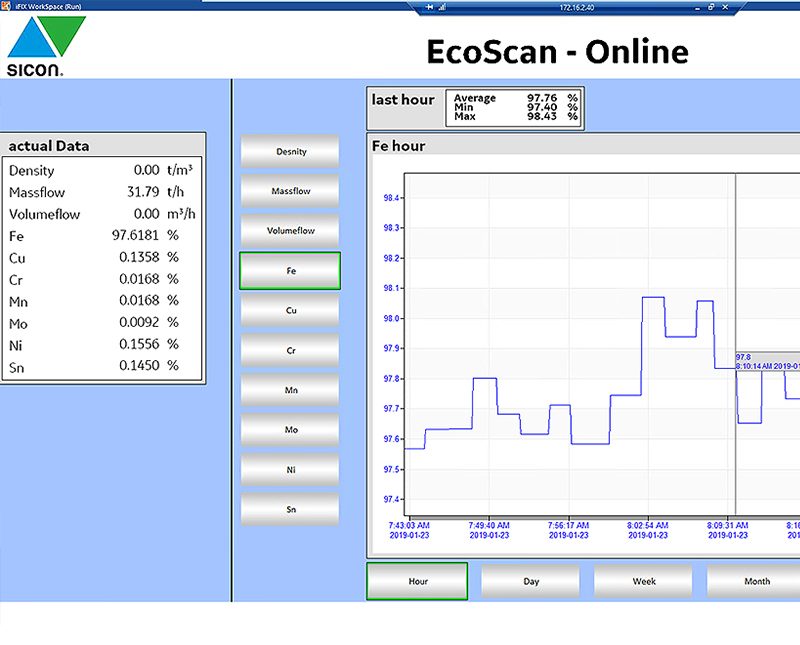

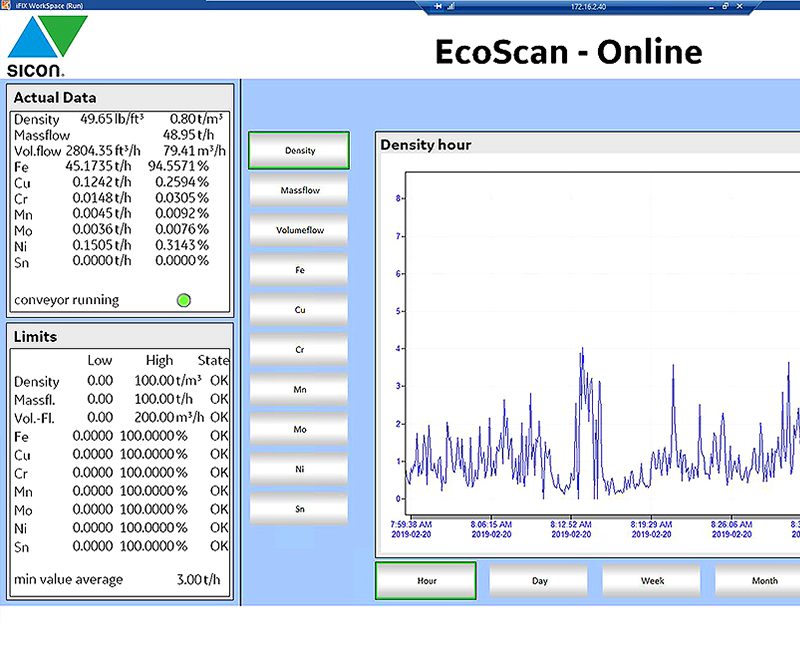

SICON has developed a two-stage solution for the steel industry that makes shredded scrap recovery even more rewarding. The EcoScan® Online is the first compact and cost-effective online analyzer that enables online inspection of scrap quality.

EcoScan® Online - Your benefits at a glance

- Permanent monitoring of the copper content in shredded scrap (also in other mixtures)

- Calibration and adaptation to a wide variety of scrap types

- Control of the bulk density (optional)

- Individual integration into existing systems

- Smart alarm system

- Detailed reporting system (individual adjustment possible)

- Optional certificate system

- Data utilization for improved plant automation

- Online control of non-ferrous scrap and rejection of inferior qualities before melting

- Many other possible applications (e.g. turnings)

Daily updated online analyses of the scrap quality

Product video

Our expert for the EcoScan® Online, Christin Roth, explains how it works and the economic advantages of online analytics.

Duration: 2.51 Minuten