EddyPro

The eddy current separator for optimised non-ferrous metal separation

Eddy current separators are used to separate non-ferrous metals (aluminum, copper, brass), i.e. electrically conductive particles, from non-conductors of all kinds. A time-varying magnetic field induces eddy currents in the conductive particles, resulting in a repulsive force effect.

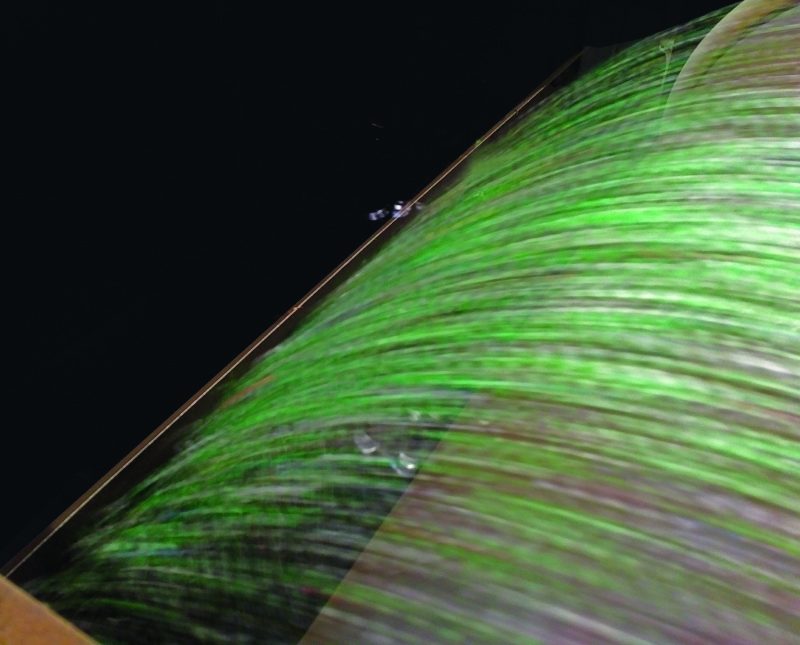

The material to be separated is fed in as thin a layer as possible and transported along the conveyor belt. It then enters the area of the rapidly rotating magnetic fields at the discharge-side deflection drum. Eddy currents are induced in the non-ferrous metal parts, which in turn build up a magnetic field around each individual particle of non-ferrous metal. The field counteracts the permanent magnetic field of the magnet rotor. As a result, a strong impulse is exerted on the non-ferrous metal parts, which flings these particles out of the flow of conveyed material.

Due to the particularly strong impulse permanent magnetic field and the high speed of the magnetic rotor, best separation results are thus achieved even with small particle sizes and fractions that are difficult to separate.

EddyPro

SICON is able to offer a new processing line that increases the efficiency of non-ferrous metal separation and improves our customers’ profitability. With the introduction of the EddyPro series eddy current separator in the US, SICON has set a new standard for the separation of non-ferrous metals.

EddyPro - Your benefits at a glance

- Excellent separation results down to grain sizes of 0.2 mm (0.008″)

- Strong and intensive impulse magnetic field

- Centric or eccentric rotor design possible

- Working widths of up to 3,000 mm (10 ft)

- Idling of conveyor belt in case of voltage drop based on energetic recovery system of the magnet rotor, thus no damage of the rotor

- Simple splitter adjustments available in single and double configurations

- Fast and easy system integration

- Belt cleaning system

- Easy maintenance due to belt changing device

- Optional: Fe separation can be integrated

Technical data

EddyPro INP

Due to the different numbers of poles and the long dwell time of the material in the magnetic field, the centric EddyPro INP allows a high specific feeding performance for materials larger than 15 mm (0.6″).

EddyPro INPx und INPxs

With an absolutely novel geometry of the magnet system, the EddyPro INPx evokes an extraordinary repulsive force in the non-ferrous parts to be separated, thus surpassing the sorting result of conventional eddy current separators. Through specific parameterization, the rotor of this separator is also capable of concentrating different non-ferrous metals from each other or even printed circuit boards from non-ferrous metals. The EddyPro INPx has a horizontal, eccentrically arranged pole wheel and uses an extremely strong neodymium permanent magnet.

The EddyPro INPxs, just like the EddyPro INPx, has a horizontal, eccentrically arranged pole wheel with neodymium permanent magnets. The large rotor diameter produces a strong, deep magnetic field and is thus particularly suitable for the deposition of finest non-ferrous metals (up to 15 mm/ 0.6″) . The ejection point is individually adjustable. Its special multi-pole magnet system produces exceptionally good separation results.

Advantages of the eccentric EddyPro at a glance

- Use of a larger rotor with a diameter of 650 mm (25.6″)

- Eccentric design for optimal use of magnetic flux

- Larger magnetic elements allow higher magnetic forces on the outer shell

- Reduced rotor speed (2,500 – 3,000 rpm) – increased performance, extended service life of rotor assembly

- Deposition of metals up to 0.2 mm (0.008″)

Rotor Competitor- Diameter ~ 200 mm (7.9″)

- smaller magnetic elements due to space contraints

- rotor must run at 4,000 rpm to generate alternative frequency

INPxs Rotor – Diameter 650mm (25.6″)

- Large magnetic elements for maximum field forces

Product video

This video explains how an eddy current separator works and also describes the input and output materials in more detail.

Duration: 1.56 minutes