EcoRip® Neo

The basis for a more efficient shredder process

Processing shredder feedstock with the aid of EcoRip® Neo always makes good sense both technically and economically. The SICON EcoRip® Neo Pre-Shredder is characterized by a high output at defined particle sizes and is also especially easy to maintain. That makes the EcoRip® Neo series the benchmark in terms of technology and efficiency when it comes to processing shredder feedstock.

The EcoRip® Neo is ideal for both pre-shredding mixed scrap with an optional integrated screening step as alternative to a guillotine shear, as well as for pre-shredding shredder input material prior to loading onto a shredder infeed conveyor. The SICON EcoRip® Neo can also be flexibly used as an effective stand- alone solution or can be subsequently added to an existing system.

Its key advantages include:

- improvement in the performance of the main shredder by up to 30 % with increased reliability (reduced wear and tear and decrease in emissions)

- lower energy costs (kWh/mt of Fe output) with improved quality of scrap (higher density)

In order to realise the advantages of the EcoRip® Neo, the control system of the main shredder is adapted by a SICON automation system.

The EcoRip® Neo leads to a considerable improvement in the performance of your shredder plant with reduced specific total cost of ownership. The result is a significantly improved competitive situation for your company.

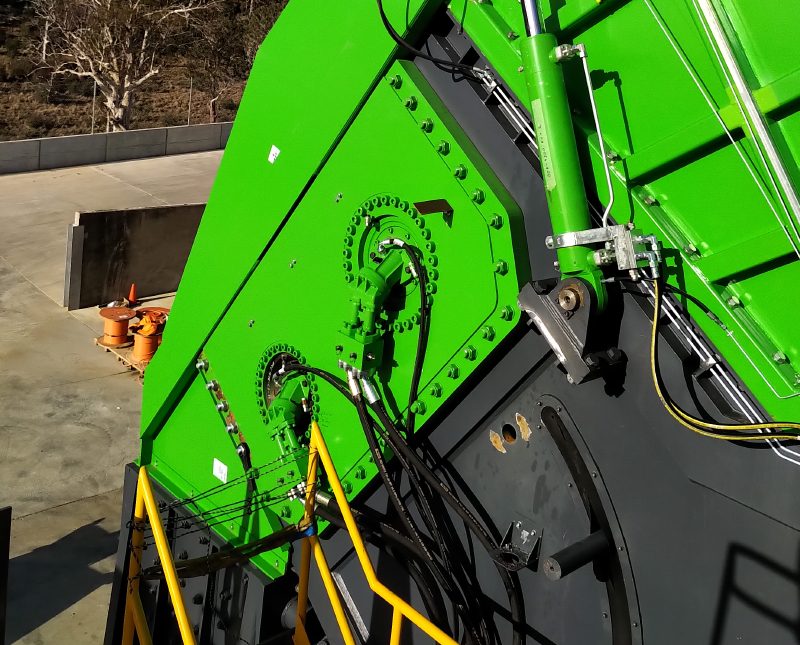

EcoRip® Neo and rotors

EcoRip® Neo is an economical alternative to the classic guillotine shear for pre-shredding mixed scrap with subsequent screening and Fe separation.

EcoRip® Neo - Your benefits at a glance

- Generating a homogeneous and coarse-grained scrap

- Material preparation for an efficient sorting of NF metals with integrated Fe separation

- Efficient separation of inert and magnetic fines (oxides)

- Optimized and faster loading of sea containers for scrap export

- Lower specific investment costs compared to conventional shredder systems

Metallurgical advantages

- Optimization of filling process of scrap baskets thanks to increase in bulk density of mixed scrap and thus improved use of space

- Decrease in number of scrap baskets used smelting process

- Higher metallurgical yields and thus lower quantities of slag

- Reduction in specific energy costs per ton of raw steel

EcoRip® Neo as upstream addition to a shredder line

- Pre-shredding of bales, auto bodies, mixed scrap – use of bales is thus also possible in smaller shredders

- Separation of inert fines with the aid of integrated screens upstream of the main shredder

- Increase in performance of main shredder (by up to 30 %) with corresponding adaptation of electronic control system of the main shredder

- Significant decrease in wear and tear of main shredder

- Prevention of explosions occurring in the main shredder, thus decrease in emissions

- The combination of EcoRip® Neo and main shredder enables SICON’s dry AirTuning exhaust purification process – Fully automatic operation of entire shredding system possible

- Increase in scrap density due to full box shredding

- Increase in recovery of NF metals thanks to improved preparation

- Quality control of baled scrap

- Prevention of unshreddables being fed into the main shredder, thus resulting in a significantly improved operational reliability

- Segmented rotor for simplified maintenance and customisation options

Input:

Altfahrzeuge

Output:

Input:

Motorschrott

Output:

Input:

Schrottpakete

Output:

Efficient pre-shredding at the highest level

The EcoRip® Neo pre-shreds ELV, scrap bales and logs and can then be processed further without any problems.

Technical data

| EcoRip® 200 Neo | EcoRip® 250 Neo | |

|---|---|---|

| Performance | ||

| Feed width [mm] | 2,000 | 2,500 |

| Top rotor (slow moving) [kW/PS] | 120 / 160 | 205 / 279 |

| Bottom rotor (fast moving) [kW/PS] | 335 / 455 | 710 / 965 |

| Flipper [kW/HP] | 22 / 30 | 37 / 50 |

| Speed | ||

| Top rotor (adjustable) [min–1] | 3-6 | 3-6 |

| Bottom rotor (adjustable) [min-1] | 14-20 | 14-22 |

| Output [mt/h] | ||

| Output [t/h]: Mixed scrap, ELVs | Up to 70 | Up to 100 |

| Output [t/h]: Bale density < 0.8 t/m³/50 lbs/ft³ | Up to 40 | Up to 70 |

| Output [t/h]: Bale density < 1.0 t/m³ /62 lbs/ft³ | Up to 30 | Up to 50-60 |

Product video

The video shows the operation and advantages of the EcoRip® Neo pre-shredder.

Duration: 1.57 minutes