EcoShred® Compact

State-of-the-art shredder technology through combined pre- and main shredder

For many years, large-capacity shredding installations were reserved primarily to a small group of financially larger scrap processors. The advantage of the EcoShred Compact made shredder technology also available to small- and medium-sized scrap processors and automobile recyclers. With the EcoShred Compact, SICON relies on modern shredder technology integrated in a modular and economically viable system. Both the technical characteristics and the low necessary infrastructure costs are impressive.

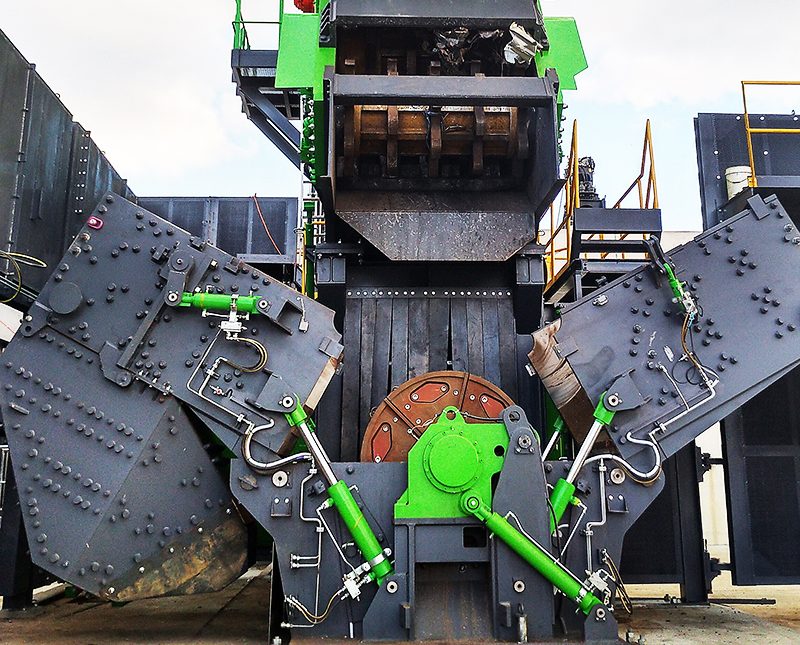

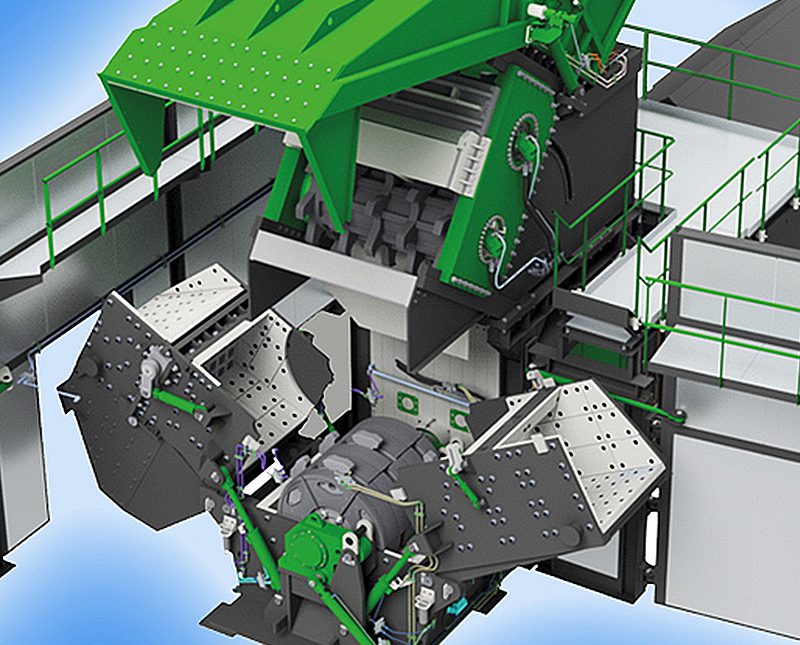

The EcoShred Compact is equipped with an integrated pre-shredder, which is implemented as a twin-shaft shredder system with flipper. The combination of pre-shredder and main shredder entails significant advantages.

Advantages of an integrated pre-shredder

- Scrap is ripped by the pre-shredder and afterwards compacted directly by the main shredder to an optimum

- The risk of explosions is decreased significantly

- Unshreddables do not enter the shredder, which results in an improved operational reliability

- Prevention of any peak loads in the main shredder (uniform power consumption)

- Bales can also be processed with a driving power of 1,000 kW

EcoShred® Compact represents a breakthrough in innovation and combination. With a system based on finely tuned components, SICON focuses on maximizing performance and energy efficiency. The combination of pre-shredder and shredder in one system results in a significant reduction in specific energy consumption per ton of shredded scrap. The finely tuned shredding stages ensure fully automatic operation, which means the system can be monitored by a single crane operator. There is no longer a need to construct separate infrastructure. The entire concept is designed with exceptional ease of operation and maintenance in mind. Additionally, the EcoShred® Compact offers numerous features that make working with and on the shredder more economical and safer than any other machines available on the market today.

Pre-Shredder

Rotor, hydraulically replaceable

Wear plates

Drive and automation

EcoShred® Compact process results in a high and consistent scrap density and thus a correspondingly good material preparation – with clear advantages for the recovery of NF metals. EcoShred® Compact forms the basis for the efficient operation of a shredder system.

The EcoShred® Compact has many features that make working on and with the shredder more economical and safer than with any other machine available on the market today.

EcoShred® Compact - Your benefits at a glance

- Shredder with integrated EcoRip® pre-shredder in one system

- High scrap density and very good material preparation by means of full box shredding

- Prevention of explosions through material preparation upstream of main shredder

- Heavy components are already identified and separated in the pre-shredder – that protects the rotor elements in the main shredder from any damage

- Prevention of peak loads with optimum energy management system

- Significantly higher output by means of an intelligent system combination as conventional shredder with the same driving power

- Easy but safe access for changing wear parts with maximum operator safety

- Significant decrease in investment with regard to power supply (low voltage 400 V / 460 V vs. high voltage 6/11 kV)

- Quick and easy installation as a result of reduced requirements on infrastructure (for instance, a simple foundation slab is sufficient and no separate operations building is required)

Input:

End-of-life Vehicles

Output:

Shredded scrap

Input:

Scrap bales

Output:

Shredded scrap

Input:

Shredded scrap

Output:

Shredded scrap

Input:

Mixed scrap

Output:

Shredded scrap

Shredding has never been easier

The EcoShred Compact® is the basis for the economical operation of a shredder plant. At the end of the process, there is a high and uniform scrap density and correspondingly good material disintegration – with advantages for non-ferrous metal recovery.

Table of technical parameters

| EcoShred® Compact | |

|---|---|

| Shredder weight [mt] | 150 |

| Rotor [mt] | 12.5 |

| Rotor design | Disk rotor with protective covers, other rotor variations possible |

| Width of feed chute [mm] | 2,000 |

| Production of shredded scrap at 1,000 kW (1,360 HP [mt/h output]) | 35-45 |

| Pre-shredder integrated | Yes |

| Scrap density [t/m³] | > 1.1 |

| Rotor lift mechanism | Included |

| Main drive concept | AC |

| Energy supply | Low voltage |

| Flicker effects, load on the power grid during peak loads | No |

| Separate operator panel | Not necessary |

| Shredder control | By crane operator via mobile tablet |

| Building for hydraulic unit and electrical | Not necessary, integrated in system concept |

| Reinforced foundation | Not necessary |

| Automation | Completely automated |

| Dust removal volume | Reduced dust removal volume, dust removal systems are offered and designed on the basis of the customer’s specific requirements |

| Occupational safety | Comprehensive safety concept |

Product video

This video explains the operation of the pre-shredder and the main shredder, and further describes the input and output materials in more detail.

Duration: 4:15 minutes