EcoShred® Cuttec

Granularors for efficient and high cutting performance

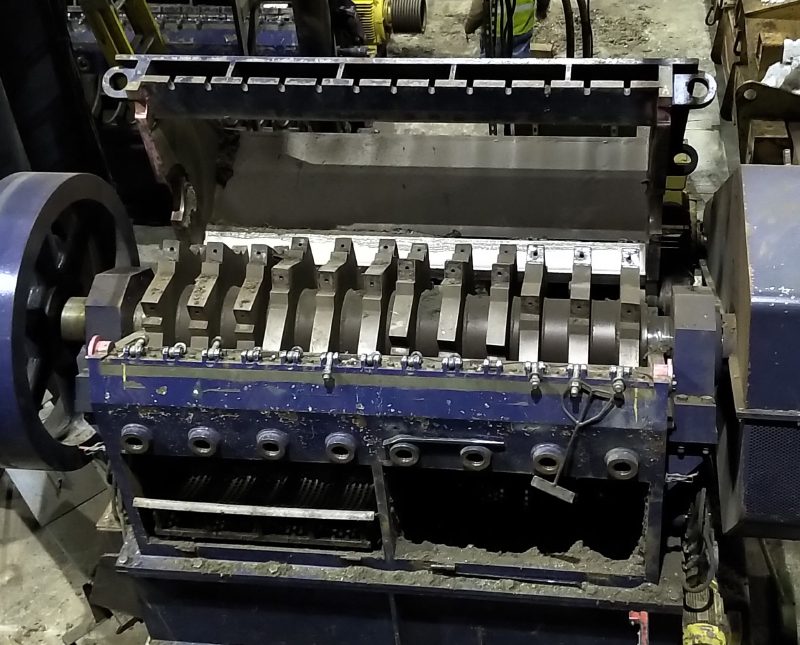

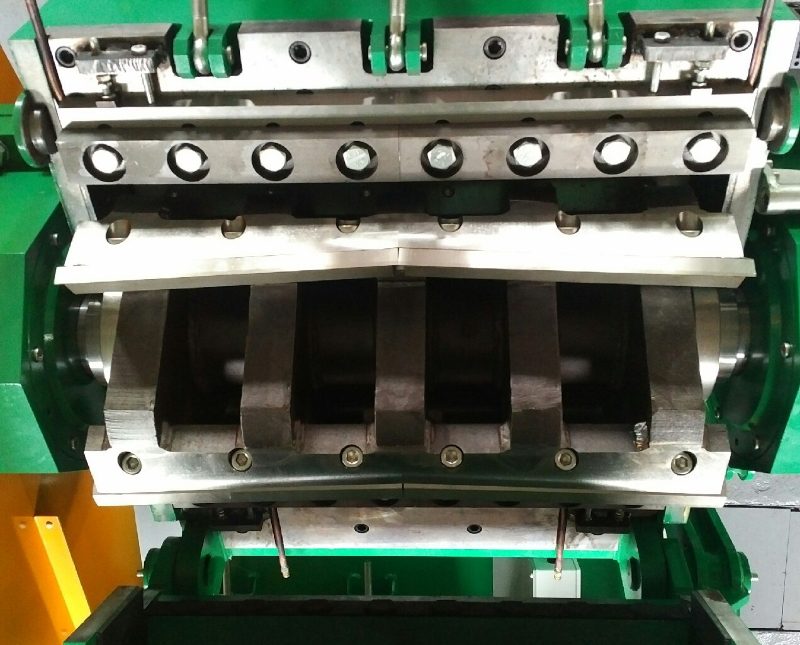

SICON’s granulator series EcoShred® Cuttec is specifically designed for highest cutting performance with lowest operational costs. To meet each individual requirement, the granulators are highly customizable in terms of different rotor and knife type configurations. SICON tests each material sample extensively and issues recommendations on the specific application set-up

EcoShred® Cuttec is equipped with a durable and easy-to-replace wear plates. Even material that causes extensive wear on other equipment can be processed with the SICON granulator with ease and minimal wear. EcoShred® Cuttec granulators are designed for a long life-cycle and can be operated around the clock.

Typical applications::

- Shredding and processing of bottles, foils, etc.

- Wire shredding

- E-Scrap processing

- Production of specified metals for final processing

SICON can integrate the granulators into your plant and plan the material pre-treatment, feeding and the material removal up to the final processing.

EcoShred® Cuttec - Your benefits at a glance

- Welded heavy-duty steel frame

- Easy-access maintenance

- Including rotor lock and rotor speed sensor for increase maintenance safety

- Optional: pneumatic transportation and dedusting unit available

- Optional: upstream material separation system available for additional protection and increase life of granulator (e.g. recommended for processing polluted material)

Input:

...

Output:

...

Input:

...

Output:

...

Table of technical parameters

| EcoShred® Cuttec | 800×520 | 1200×660 |

|---|---|---|

| Dimension (L/W/H) [mm] | 2,170×1,785×3,100 | 2,165×2,165×3,330 |

| Hopper Inlet (L/H) [mm] | 750×820 | 1,150×1,020 |

| Rotation Diameter [mm] | Ø 520 | Ø 660 |

| Operation Length [mm] | 800 | 1,200 |

| Rotation Speed [rpm] | 520 | 520 |

| Rotor Knives [PCS] | 5×2 | 7×2 |

| Counter Knives [PCS] | 3×1 | 3×2 |

| Main Drive [kW] | 55~75 | 90~132 |

| Hydraulic Power Pack [kW] | 1.5 | 1.5 |

| Weight approx. [kg] | 4,400 | 7,250 |

(other sizes on request, subject to change)