The processing of cables separated from shredder residues, whether from the light or heavy shredder fraction, can be challenging. Depending on the upstream separation technology, the cables may be more or less contaminated with dirt and other metallic impurities. In the case of cutting shredding, this leads to incalculable costs and damage.

In addition, complete separation between copper and aluminum on the one hand and separated cable insulation on the other can only be achieved after pelletizing, which means that most plants require an additional machine. Approaches using so-called turbo mills have also frustrated many operators.

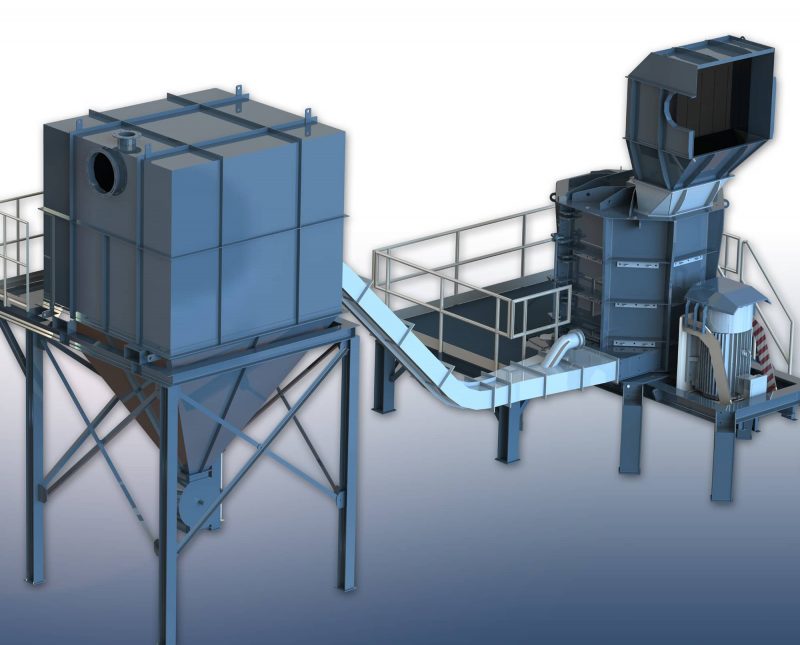

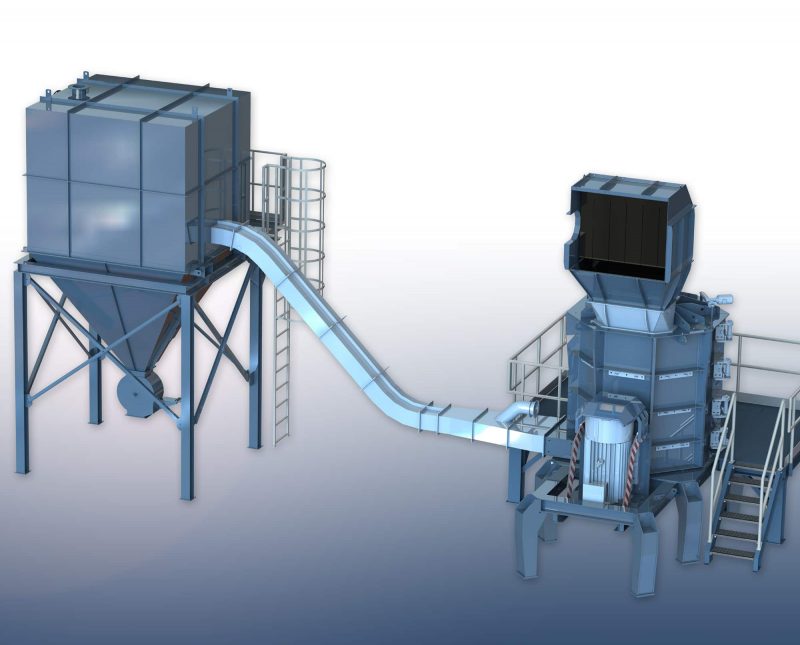

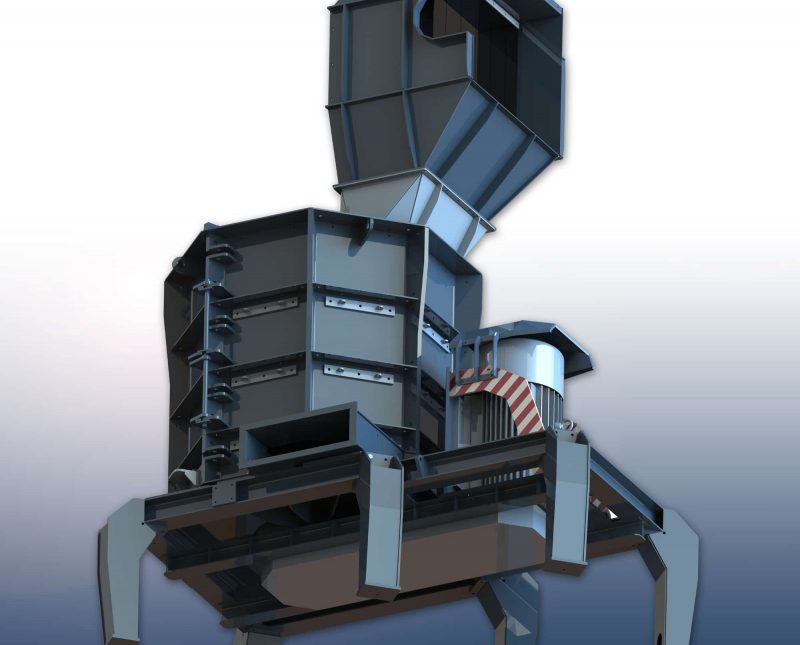

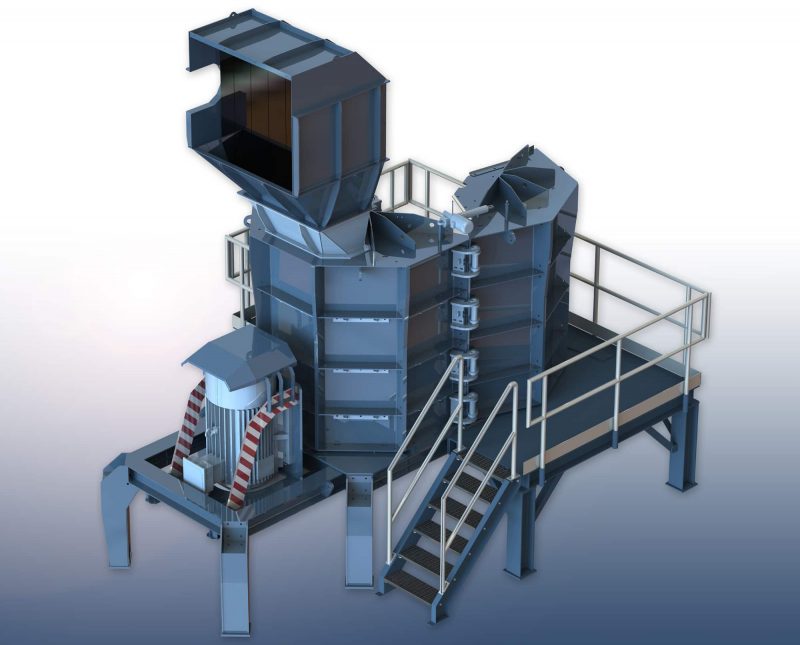

SICON presents the solution, the EcoShred® Wiretec: a vertical hammer mill that can be operated in reverse. In a single pass, it enables the following steps on 5 grinding levels:

• the effective breakdown of non-ferrous metals and insulation,

• the balling of non-ferrous metals,

• and the magnetization of stainless steel components for further separation.

Thanks to its non-cutting shredding principle, the Wiretec is extremely low-wear and avoids the typical problems associated with conventional cutting technology.

SICON also carries out the upstream and downstream processing steps (screening, separation, etc.), thus ensuring perfect sorting results.